Email

Contact No

+91 22 40620000

THERMO ELECTRIC MODULE

An Introduction To Thermoelectric cooling module

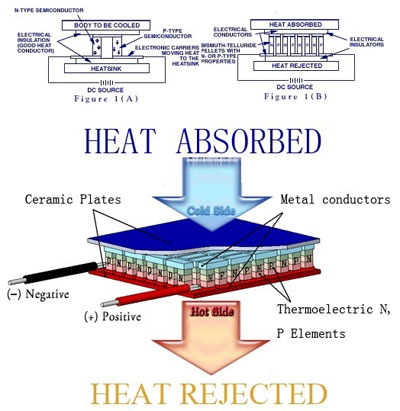

Thermoelectric technology is an active thermal management technique based on the Peltier effect. It was discovered by J.C.A Peltier in 1834, this phenomenon involves the heating or cooling of the junction of two thermoelectric materials(bismuth and telluride) by passing current through the junction. During operation, direct current flows through the TEC module causing heat to be transfered from one side to the other. Creating a cold and hot side. If the direction of the current is reversed, the cold and hot sides are changed. Its cooling power also can be adjusted by changing its operating current. A typical single stage cooler (Figure. 1) consists of two ceramic plates with p and n-type semiconductor material (bismuth ,telluride) between the ceramic plates. The elements of semiconductor material are connected electrically in series and thermally in parallel.

Thermoelectric cooling module, Peltier device,TEC modules can be considered as a type of solid-state thermal energy pump, and due to its actual weight, size and the rate of reaction, it is very suitable to be used as part of the inbuilt cooling systems (due to limitation of space). With advantages such as quiet operation, shatter proof, shock resistance, longer useful life and easy maintenance, modern thermoelectric cooling module,peltier device,TEC modules have a wide range application in the fields of military equipments, aviation, aerospace, medical treatment, epidemic prevention, experimental apparatus, consumer products (water cooler, car cooler, hotel refrigerator, wine cooler, personal mini cooler, cool & heat sleep pad, etc).

Today, because of its low weight, small size or capacity and low cost, thermoelectric cooling is widely used in medical, pharmaceutical equiment, aviation, aerospace, military, spectrocopy systems, and commercial products(such as hot& cold water dispenser, portable refrigerators, carcooler and so on)

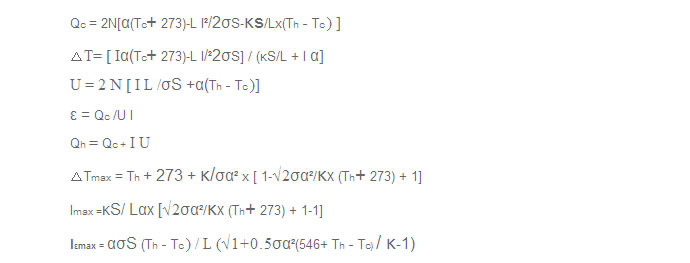

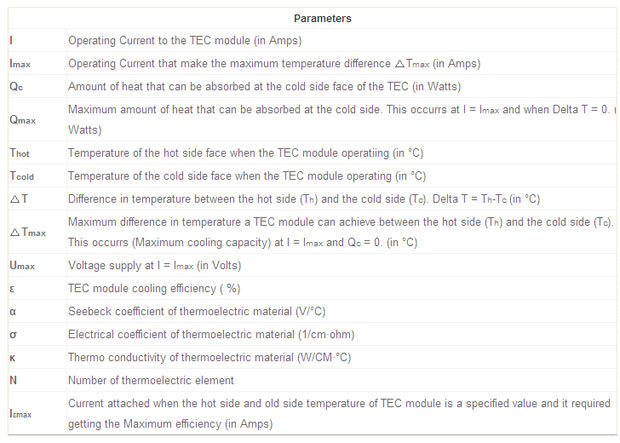

Introduction of application Formulae to TEC module